Ever walked into a hospital room or a construction site and seen a large machine quietly humming away? That’s a negative air machine at work, and it’s a critical player in maintaining clean, safe environments. By creating a vacuum effect, it pulls contaminated air through specialized filters, trapping harmful particles and ensuring that the air we breathe is free from pollutants. Whether it’s controlling infections in a hospital or containing dust during renovations, these machines are indispensable. So, what does a negative air machine do? It ensures the air around us is clean and safe.

What Does a Negative Air Machine Do?

History, Origins and Development of Negative Air Machines

Negative air machines have an interesting history. Initially developed for medical settings to prevent the spread of airborne contaminants, these machines have evolved significantly over the years. Early models were rudimentary, focusing mainly on creating a pressure differential to contain harmful particles.

Early Uses and Innovations

In the early days, negative air machines were primarily used in hospitals during outbreaks of infectious diseases. Innovations over time have expanded their applications to various industries, making them more versatile and efficient.

What Does a Negative Air Machine Do

The fundamental principle behind a negative air machine is simple yet effective. It creates a vacuum effect by pulling air through filters, trapping contaminants, and then exhausting the clean air out.

Negative pressure air machines not only clean the air, they also generate positive or negative pressure. Negative pressure isolates the space and prevents pathogens from spreading out of the room, while positive pressure protects the people in the room from outside air that could cause harm to immunocompromised patients.

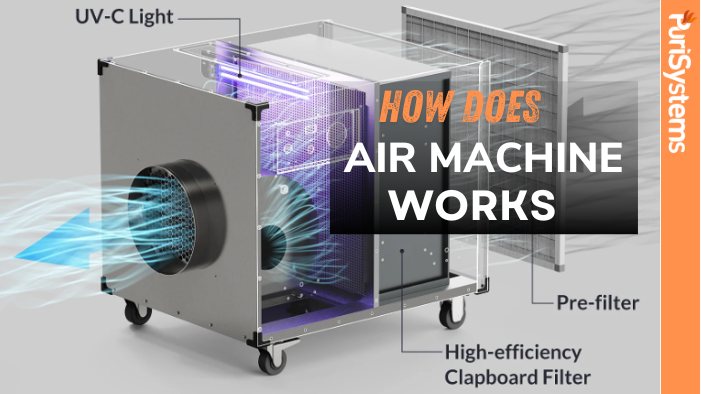

Components of a Negative Air Machine

-

Filters

Filters are the heart of any negative air machine. They trap dust, mold spores, bacteria, and other contaminants. HEPA filters are particularly effective, capturing particles as small as 0.3 microns with 99.97% efficiency.

-

Blower

The blower is responsible for creating the airflow necessary to pull contaminated air through the filters. It needs to be powerful enough to maintain a consistent flow rate, ensuring that all air in the space is continuously filtered.

-

Ductwork

Ductwork is used to direct the flow of air into and out of the negative air machine. Properly designed ductwork ensures that the machine operates efficiently and that the clean air is adequately distributed.

Types of Negative Air Machines

-

Portable Negative Air Machines

Portable negative air machines are versatile and can be moved easily from one location to another. They are ideal for temporary setups and small-scale projects.

-

Fixed Negative Air Systems

Fixed negative air systems are permanently installed in a facility. They are suitable for large-scale operations and areas that require continuous air quality control.

Applications of Negative Air Machines

Healthcare Settings

-

Hospitals

In hospitals, negative air machines are crucial for infection control. They are used in isolation rooms to prevent the spread of airborne diseases, ensuring that patients and staff remain safe.

-

Clinics

Clinics, especially those dealing with respiratory illnesses, also rely on negative air machines to maintain a sterile environment and protect vulnerable patients.

Construction and Renovation

-

Asbestos Removal

Negative air machines are vital in asbestos removal projects. They prevent asbestos fibers from contaminating the surrounding areas, protecting workers and residents from potential health risks.

-

Mold Remediation

During mold remediation, these machines help contain and eliminate mold spores, ensuring that the treated area remains safe and mold-free.

Industrial Use of Negative Air Machines

-

Manufacturing Plants

In manufacturing plants, negative air machines help manage dust and fumes, maintaining a clean working environment and ensuring compliance with health and safety regulations.

-

Cleanrooms

Cleanrooms require stringent air quality controls. Negative air machines are used to maintain the required cleanliness levels by continuously filtering the air and preventing contamination.

Benefits of Using Negative Air Machines

-

Improved Air Quality

One of the primary benefits of using negative air machines is the significant improvement in indoor air quality. By removing contaminants, these machines ensure that the air you breathe is clean and safe.

-

Health and Safety

Negative air machines play a crucial role in protecting the health and safety of individuals in various settings. They help prevent the spread of infectious diseases, reduce exposure to harmful particles, and maintain a safe environment.

-

Regulatory Compliance

Using negative air machines helps businesses comply with health and safety regulations. This compliance is essential for avoiding fines and ensuring the well-being of employees and customers.

Choosing the Right Negative Air Machine

Assessing Needs

Before choosing a negative air machine, it's essential to assess your specific needs. Consider the size of the area, the types of contaminants, and the required filtration efficiency.

Key Features to Look for in Negative Air Machine

-

Filtration Efficiency

Look for machines with high-efficiency filters, such as HEPA filters, to ensure maximum removal of contaminants.

-

Airflow Capacity

The airflow capacity of the machine should match the size of the area you need to cover. Higher capacity machines are required for larger spaces.

-

Noise Levels

Consider the noise levels of the machine, especially if it will be used in occupied spaces. Quieter models are preferable for environments like hospitals and offices.

Installation and Maintenance

-

Proper Setup

Proper installation is crucial for the effective operation of a negative air machine. Ensure that the machine is correctly positioned and that the ductwork is properly connected.

Regular Maintenance Tips

-

Filter Replacement

Regularly replace the filters to maintain the machine's efficiency. Clogged filters can reduce airflow and compromise the machine's performance.

-

Blower Maintenance

Keep the blower clean and well-maintained to ensure consistent airflow. Regular checks and servicing can prolong the life of the machine.

Conclusion

In summary, what does a negative air machine do? It plays a crucial role in safeguarding our environments by effectively removing airborne contaminants. Whether in healthcare settings, construction sites, or industrial facilities, these machines ensure the air remains clean and safe, protecting both health and compliance with regulations. By understanding their operation, benefits, and proper maintenance, you can leverage these machines to create healthier spaces. From improving air quality to preventing the spread of infections, negative air machines are essential tools in our modern world.

FAQs about the Working of Negative Air Machine

What size negative air machine do I need?

The size of the negative air machine you need depends on the area you want to cover. Larger spaces require machines with higher airflow capacity.

Can I use a negative air machine at home?

Yes, negative air machines can be used at home, especially in situations where air quality needs to be controlled, such as during renovations or mold remediation.

How often should I replace the filters?

Filters should be replaced regularly, depending on the usage and the type of contaminants. Check the manufacturer's recommendations for specific guidelines.

How do negative air machines' energy efficiency?

The energy consumption of a negative pressure air machine depends on the appliance's power. The wattage indicates the appliance's electricity per hour, and many air scrubbers have adjustable speeds. At higher speeds, it consumes more energy. So adjust the speed and operating time according to your needs in good time.